ERUI:EFFICIENT SUPPLY CHAIN

ERUI:EFFICIENT SUPPLY CHAIN

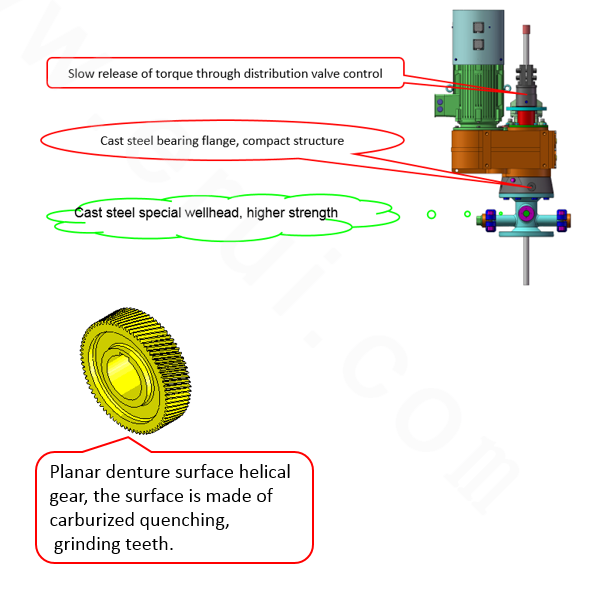

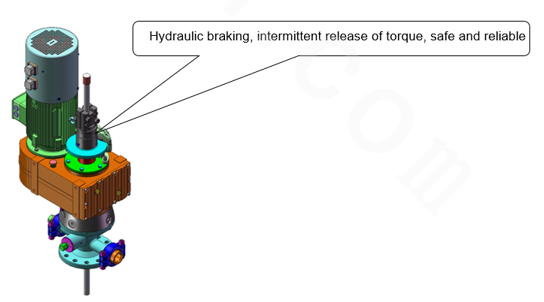

Separated Layer Water Injection Technology

Water Shut-off and Profile Control Technology

We demonstrate the working scene of oil and gas energy field, which help you quickly select the products you need.