1. Introduction

Oilfield digitization can generally be described as: taking oilfields as the research object, using computers and high-speed networks as carriers, and using spatial coordinate information as a reference to highly integrate various data of oilfield production and management. Based on the establishment of various optimization models of oilfield production and management processes, simulation and virtual technologies are used to visualize data in multiple dimensions, so as to realize the horizontal coverage of the entire oilfield area, and the vertical position of the oilfield from the ground to the underground. The overall information analysis capabilities of the oilfield to support the in-depth needs of key businesses such as oilfield exploration and development. As a whole, it assists the decision-making analysis of oilfield operation and management, and further explores the potential value of each link to create a good information support environment for the sustainable development of oilfield enterprises.

Digitization is the forefront of production in the overall information architecture. It focuses on the production process monitoring of basic units such as wells, stations, pipelines, and completes data collection, process monitoring, and dynamic analysis to find and solve problems to maintain normal production. Establish a unified data interface with other systems to realize data sharing. An information system based on production process management is an extension and expansion of the oilfield information system. The construction of all management subsystems is mainly for monitoring, analyzing, optimizing and updating all aspects related to actual production to achieve the goal of efficient and intelligent enterprise management. The digital management process of the oil field includes the data acquisition system, the well station monitoring platform, the production management platform of the plant and the operation area, etc.

2. Necessity

2.1 This is the need to improve the working environment of the oilfield

a.The environmental conditions of the oil field are harsh.

-

The production site is located in a remote mountainous area, Gobi or desert;

-

The site environment is harsh with extreme high/low temperature;

-

In some areas, there are heavy thunder and lightning, salt fog/acid fog corrosion is serious.

b. Oilfield production conditions are restricted.·

-

The production and living conditions of front-line personnel are difficult;

-

Daily production inspections have poor traffic conditions and long inspection cycles;

-

The equipment account is chaotic, the equipment maintenance is difficult, and the downtime of failure remains high.

c. There are health, safety and environmental risks.·

-

High temperature, high pressure, toxic and harmful working environment;

-

Severe climatic environment, poor working conditions of operators and high operating costs;

-

The aging and corrosion of equipment and facilities have caused oil and gas leakage;

-

Leakage of flammable gas, causing safety accidents such as fire, threatening personal and property safety;

-

Oil and gas leakage causes environmental pollution and damage to the ecosystem.

2.2 This is the need to improve work efficiency and improve management level.·

a. The traditional manual inspection mode has high labor intensity and low work efficiency;

b. Production data relies on manual entry and reporting, with missing records and poor data reliability;

c. Failure discovery and processing response is slow, failure downtime is long, and production efficiency is low;

d. Traditional management methods are inefficient, difficult to collect and share production data, and high costs.

Erui provides customized professional solutions for different oilfields' digital level and needs.

3. Technology Classification

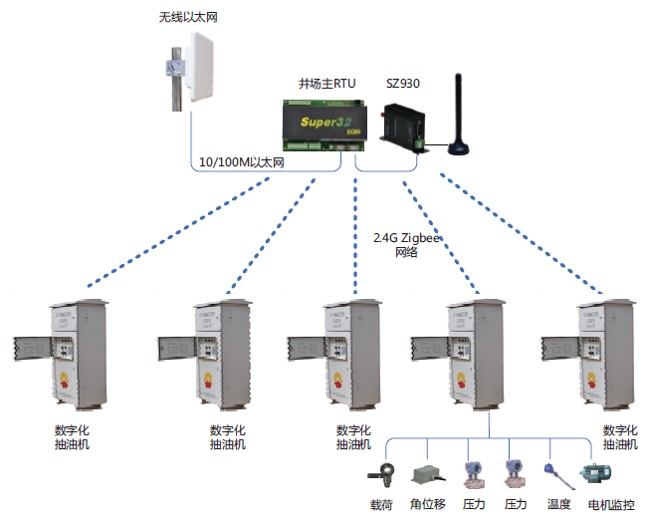

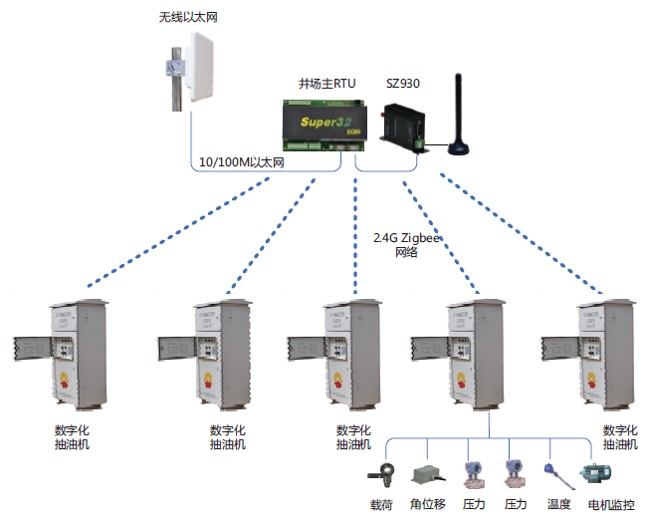

Digitalization construction of the well stations and fields. Through wired and wireless network communication, the terminal and the upper computer system are connected, which helps to transmit data and remote control. It sets up a data collection and supervision system covering the whole oil and gas fields to realize the efficient and intelligent control of oil field development and operation. It can collect and analyze information in time, improve management efficiency, and reduce manpower and material resources consumption.

The acquisition and control of subsystem construction is the foundation of the entire "Internet of Oil and Gas Production". Using sensor, radio frequency and other technologies to sense oil and gas production information, establish an accurate and reliable automatic acquisition and control subsystem covering the entire oil and gas process, to achieve complete and accurate data collection, accurate process control, timely and effective safety management, and stable and reliable system control.

3.1 Oil Well Digitalization Solution

With digitalized connection, data acquisition and control can be carried out for the oil wellhead on site and the instrument data collected from the well field can be transmitted to the central control room to realize energy-saving control such as remote start/stop, empty pumping, intermittent pumping, and frequency conversion control.

3.2 Water Well Digitalization Solution

Data such as pressure of water injection well and water injection volume can be collected to realize water remote distribution in the central control room, reduce labor intensity, and automatically adjust water injection volume. Three-phase electrical parameters of the water source well motor and flowmeter data can be collected. The water level of the well can be measured and an alarm can be given according to the water level. The start/stop, drainage and water supply of the well can be remotely controlled.

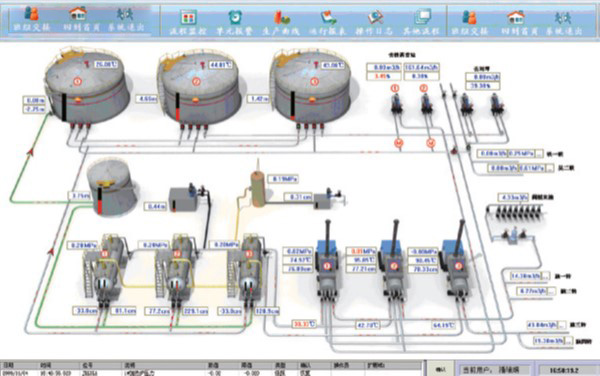

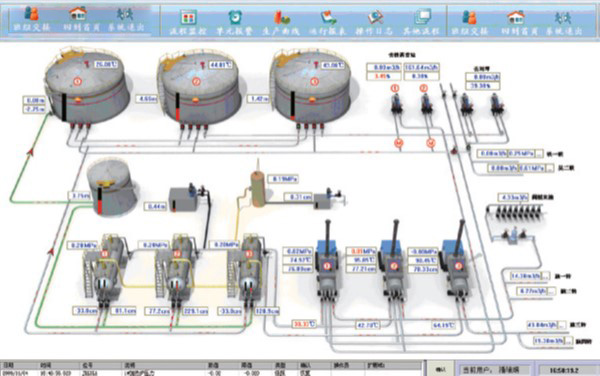

3.3 Multi-purpose Station Digitalization Solution

With the PlantE5000 DCS system, the process flows in the multi-purpose station in the oil production area can be controlled. Erui provides an overall automation solution to realize the efficient management of the oil field. The level monitoring and control system equipped for the fire water tank can control the start and stop of fire pumps and concentration data of combustible gas in equipment rooms in real time to ensure safe production in the oilfield.

4. Service Process

Erui can provide digitalized solutions, digitalized software and hardware products, site instruction and technical services according to customers’ needs. If you are interested in our products or technology, please follow the process below:

4.1 Please put forward the purpose and requirements of the digitalized construction of your oilfield;

4.2 Please provide the current basic information of your digitalized oilfield.

4.3 Communication by email or social software for technical and commercial information;

4.4 Erui provide a proposal as required;

4.5 Confirm the proposal, and sign a cooperation agreement;

4.6 Provide overall solutions, process design, products or on-site construction instruction according to the contract;

5. Related Scene Display

Click the picture to read more details:

You can click to >>contact us<< or directly by phone or email:

TEL.: 400-820-9199

E-mail: sales@erui.com