ERUI:EFFICIENT SUPPLY CHAIN

ERUI:EFFICIENT SUPPLY CHAIN

1. Introduction

Loose sandstone and long-term water flooding oil wells will cause a large amount of sand production in oil wells. In order to prevent sand production, on the one hand, correctly choose cementing and completion methods according to oil layer and oil well conditions, then make reasonable production measures and control production pressure difference; On the other hand, according to the requirements of the oil layer and the production process, the corresponding sand control technology is adopted to ensure the normal production of the oil well.

2. Necessity

Sand production in oil wells brings many hazards, mainly in three aspects:

It is easy to cause pump jams and make oil wells unable to produce normally, which not only directly affects the productivity of oil wells and the output of oil fields, increases the workload of pump inspection and sand washing in oil production operations, but also causes abrasion to oil production equipment;

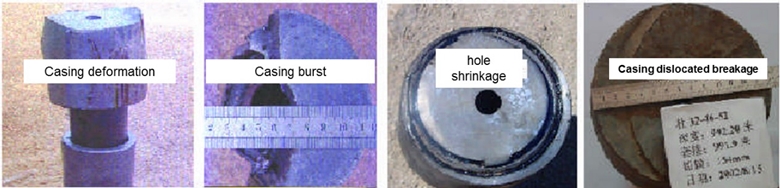

For oil wells with layered mining, a large amount of sand will bury the downhole packer and tubing string, causing sand jam accidents or the downhole tubing string being pulled off;

When the sand production is severe, it will cause the well wall and even the oil layer to collapse and damage the casing, and even cause the oil well to be scrapped. These hazards not only increase the production cost of crude oil, but also increase the difficulty of oilfield exploitation.

3. Technology Classification

Erui can provide mechanical and chemical sand control technologies.

Mechanical sand control refers to the use of mechanical methods to hang screens in the wellbore or fill gravel into the formation to form a sand-retaining barrier to achieve the purpose of sand control.

Mechanical sand control mainly includes: suspending sand control string technology, circular filling technology for wire-wrapped screen pipe and high-pressure one-time filling sand control technology .

Chemical sand control is to squeeze a certain amount of chemical agent or a mixture of chemical agent and mortar into the stratum to achieve the purpose of filling and consolidating the stratum and improving the strength of the stratum.

Chemical sand control mainly includes: ERFS-1 sand inhibitor, ERFS-S Low-damage sand consolidation agent and ERFS-T resin coated sand chemical sand control technology.

4. Mechanical Sand Control

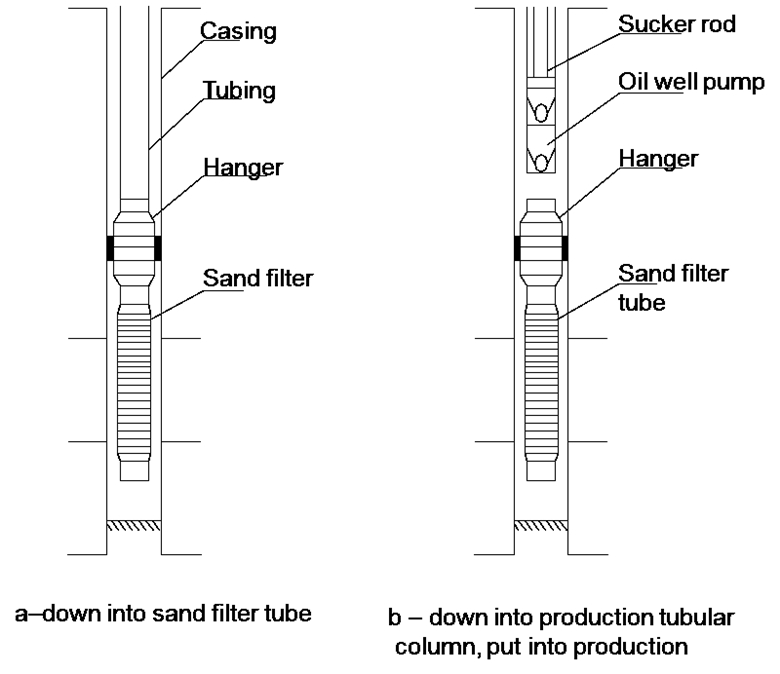

4.1 Hanging sand control column technology: a sand control technology that directly connects the screen pipe under the pump or loses the sand control screen to prevent formation sand from entering the pump barrel, which is suitable for light sand wells. It has the advantages of mature technology, simple construction and low cost.

This technology has been adopted to Well *679 of an oil field in Kazakhstan. The sand yielding period has been prolonged 417 days.

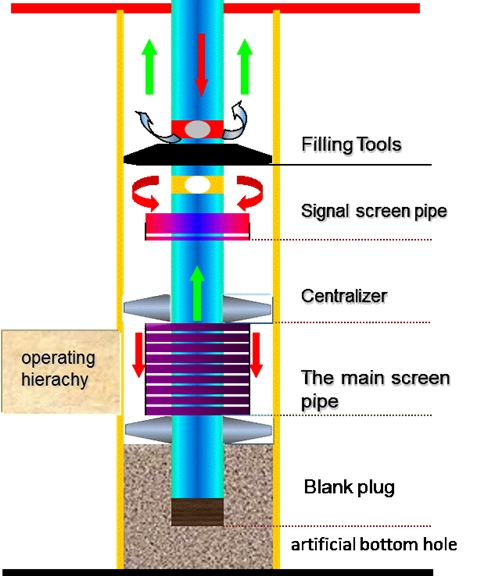

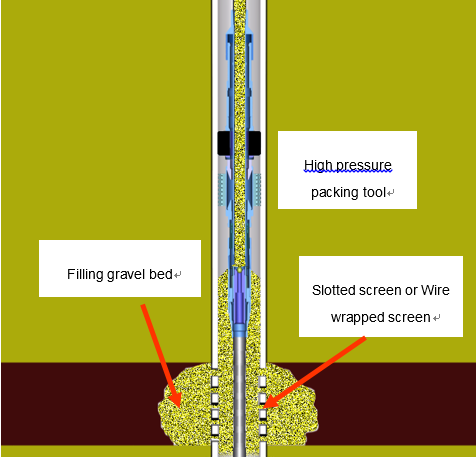

4.2 Circular filling technology for wire-wrapped screen pipe: wire-wrapped screens of corresponding sizes are placed into the oil well, then the gravels with appropriate grain size are put into the hollow place between screens and casing to create a secondary interception and filtration system, which not only ensures the smooth flowing of formation fluid, but also controls sand in the oil well and maintain a high yield. This technology is suitable for oil wells with good fluid supply, low clay content, well-sorted formation sand, large grain sizes and low crude oil viscosity. It costs less and has lower requirement for equipment.

For example, the Well 43-1 in an oil field of CNPC was filled with 10 tons of quartz sand, and the validity period of sand control is 735 days, and the average daily oil production is 11.2 tons.

4.3 The high-pressure one-time filling sand control technology: by filling sand particles with uniform grain sizes and good roundness into stratum, it improves the seepage conditions near the well zone and enlarge seepage area, which efficiently prevent blocking. This technology can keep longer work term and is suitable for low-yield wells, muddy silty-fine sand wells and heavy oil wells.

For example, China Shengli Oilfield * 4-H10 well, 70 tons of 0.4-0.8mm quartz sand was evenly added into 260 cubic meters clean fracturing fluid, then the mixed fluid was extruded and poured into the well. The construction displacement is 2.0-2.5m3/min for sand control and the sand ratio is controlled at 5-40. After the completion of construction, the sand control period lasts more than three years and the oil is increased 6000 tons (116800bbl) totally.

4.4 Fracturing sand control technology:Fracturing sand control technology is a kind of production increase sand control technology effectively integrating the sand control technology with the fracturing process. After the fracturing sand control tubular column is tripping in, the formation shall be pressed into a short and wide crack. The crack shall be filled with considerable gravel. Then, the pipe shall be subject to circulating filling with annular gravel. The advantage is that the radius of sand control transformation is large and the comprehensive effect of increasing production is strong. The disadvantage is that the cost is too high.

5. Chemical Sand Control

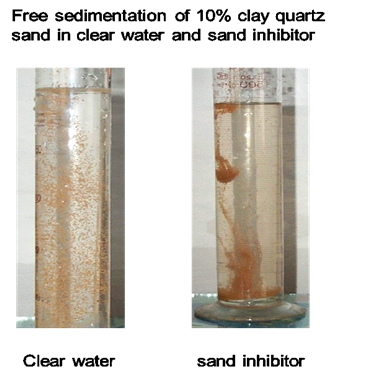

5.1 ERFS-1 sand inhibitor is a high molecular cationic polymer, together with sand and clay particles, forms large network structure so as to stabilize the stratum by winding and prevent sand yielding. It is suitable for light sand wells, and has the advantages of simple construction and low cost.

Case: Shengli Oilfield of SINOPEC, applied sand inhibitor to 246 wells one year, and achieved an effective rate of 81.3%; the average maintenance interval of oil wells was extended from 103 days to 254 days.

5.2 ERFS-S Low-damage sand consolidation agent :after being injected into the stratum, the low-damage sand stabilizer with resin as the main cementing agent can solidify the formation sand into a sand barrier with certain strength and permeability under the effect of formation temperature and internal and external curing agents to prevent sand being yielded from the stratum. It is suitable for sand control in non-fine sand reservoirs, and has the advantages of better effect and lower cost.

Case:From June 2010 to October 2011, a total of 21 sand-producing wells in one oilfield of Sinopec Shengli have applied this technology. 19 wells were successfully sand-fixed and 2 wells were invalid, with a success rate of 90.5%.

5.3 ERFS-T resin coated sand chemical sand control technology: A layer of resin shall be uniformly coated on the outer surface of quartz sand by a physicochemical method, and it will be solidified at normal temperature and converted into non-sticky stable particles, which will be carried to the sand yielding position of an oil well by the sand carrying liquid. Then, it will be extruded out of a casing for full filling. When the resin on the gravel surface softens, adheres and consolidates to form an artificial borehole wall with good permeability and strength, sand yielding from the oil reservoir can be prevented. This method is suitable for oil wells with serious leakage.

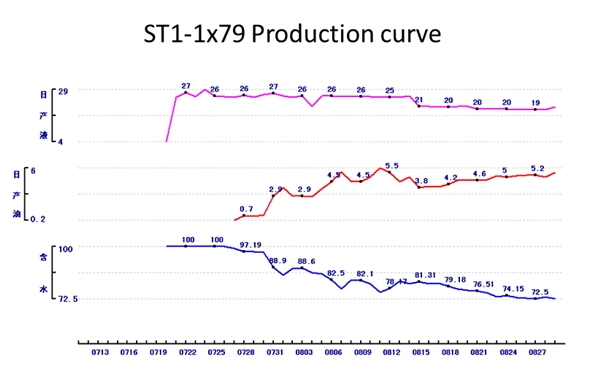

Case: On July 16, 2012, Shengli Oilfield of Sinopec applied this technology to *1-1X79 well at the first time. Until July 2014, a total of 52 wells were implemented, with an effective rate of 96.9% and the sand control effective period reaches more than 700 days.

Typical case: Well ST1-1X79 in an oil field of Sinopec

Reservoir S二12-23 is with a thickness of 4m and serious formation leakage. Sand control was carried out on July 16, 2012, and the well was opened on July 20, 2012. Safe production lasted 742 days, with a total oil production of 5442.7 tons and an average daily production of 3.39 tons.

6. Service Process

ERUI can provide overall solutions for sand control technology, process design, related products and on-site construction instruction services. If you are interested in our products or technology, please follow the process below:

6.1 Provide basic information and requirements of sand-producing oil/water wells;

6.2 Communicate technical and commercial information by email or social software;

6.3 Erui provide a proposal as required;

6.4Confirm the proposal, and sign a cooperation agreement;

6.5 Provide overall solutions, process design, products or on-site construction guidance according to the contract;

7. Releted Display Scene

Click the picture to read more details:

You can click to >>contact us<< or directly by phone or email:

TEL.: 400-820-9199

E-mail: sales@erui.com

Separated Layer Water Injection Technology

Water Shut-off and Profile Control Technology

Removal & Anti-paraffin Technology

We demonstrate the working scene of oil and gas energy field, which help you quickly select the products you need.