ERUI:EFFICIENT SUPPLY CHAIN

ERUI:EFFICIENT SUPPLY CHAIN

well number |

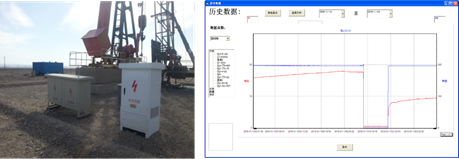

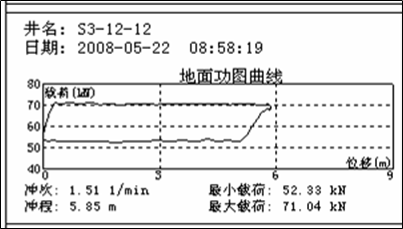

Condition before washing well |

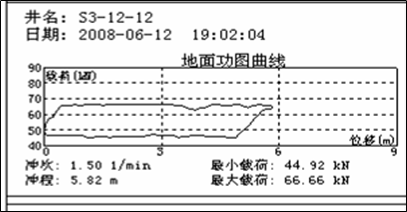

Condition before after well |

||

S3-12-12 |

Current(Max/Min, A) |

Load(Max/Min, KN) |

Current Max/Min, A |

Load(Max/Min, KN) |

10.5/9.3 |

71.04/52.33 |

9.5/9 |

66.66/44.92 |

|

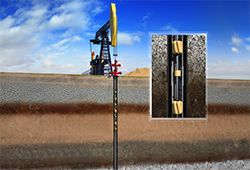

Separated Layer Water Injection Technology

Water Shut-off and Profile Control Technology

We demonstrate the working scene of oil and gas energy field, which help you quickly select the products you need.