ERUI:EFFICIENT SUPPLY CHAIN

ERUI:EFFICIENT SUPPLY CHAIN

Corrosion and Scale Inhibition Technology

Crude Oil Demulsification Technology

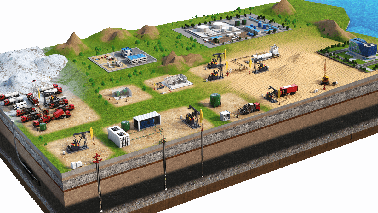

We demonstrate the working scene of oil and gas energy field, which help you quickly select the products you need.