ERUI:EFFICIENT SUPPLY CHAIN

ERUI:EFFICIENT SUPPLY CHAIN

Corrosion and Scale Inhibition Technology

1. Introduction

Corrosion and scale inhibition technology refers to the development, evaluation and application of chemical substances or chemicals that can disperse insoluble inorganic salts in water, prevent or interfere with the precipitation and scaling of insoluble inorganic salts on metal surfaces, and can prevent or slow down the corrosion of materials. Composite technology.

The mechanism of action of corrosion and scale inhibitors is divided into: complexation and solubilization, lattice distortion, and electrostatic repulsion.

1.1 Complexing and solubilization: the copolymer dissolves in water and ionizes to form a negatively charged molecular chain. It forms a water-soluble complex or chelate with Ca2+, thereby increasing the solubility of inorganic salts. Play a role in scale inhibition.

1.2 Lattice distortion effect: part of the functional groups in the molecule occupy a certain position on the inorganic salt crystal nucleus or crystallite, hindering and destroying the normal growth of the inorganic salt crystal, slowing down the growth rate of the crystal, thereby reducing The formation of salt scale.

1.3 Electrostatic repulsion effect: the copolymer is dissolved in water and adsorbed on the crystallites of the inorganic salt, which increases the repulsion between the particles, prevents their coalescence, and keeps them in a good dispersion state, thereby preventing or reducing the formation of scales.

2. Necessity

With the passage of oilfield development time, the water production of oil wells continues to increase, and the corrosion structure of the wellbore and its surrounding areas and gathering pipelines is very serious. In the long-term production practice, the hazards of scaling are mainly manifested in the following aspects:

1. Scaling on the inner wall of the downhole pipe string will cause different degrees of blockage and pipeline corrosion.

2. Scaling of oil and gas passages in underground rock formations causes the production of oil wells to decrease, the life of the facilities is shortened, and the energy consumption increases, and in severe cases, production is stopped.

3. The fouling of the gathering and transportation system causes the increase of the transportation pressure, the decrease of the transportation capacity, and even the blockage of the transportation.

4. Severe corrosion and scaling will cause production losses and even scrap oil and gas wells.

3. Classification

Commonly used corrosion and scale inhibitors in oilfield water treatment include polyphosphate, organic phosphonic acid, phosphonic acid, organic phosphonate, polycarboxylic acid, etc.

Polyphosphate: The commonly used polyphosphates are sodium tripolyphosphate and sodium hexametaphosphate. Long-chain anions formed in water are easily adsorbed on tiny calcium carbonate crystals. Also, this anion is easy to replace with CO32-, thus preventing calcium carbonate. Of precipitation.

Organic phosphonic acids: ATMP, HEDP, EDTMPS, DTPMPA, PBTCA, BHMT, etc. are commonly used, which have a good effect on inhibiting the precipitation or precipitation of calcium carbonate, hydrated iron oxide or calcium sulfate.

Organic phosphonates: The effect of inhibiting calcium sulfate scale is better, but the effect of inhibiting calcium carbonate scale is poor. It has low toxicity and is easily hydrolyzed.

Polycarboxylic acids: It has a good scale inhibition effect on calcium carbonate scale, and the amount is very small. Commonly used are polyacrylic acid PAA, hydrolyzed maleic anhydride HPMA, AA/AMPS, multi-component copolymers, etc.

3.1. ERZG-1 slow release scale inhibitor

This product is a water-soluble polymer, a new type of green water treatment agent, with the characteristics of non-phosphorus, non-toxic, non-pollution and completely biodegradable. It has a strong chelating ability to ions and a good scale inhibition effect on calcium carbonate and other scale-forming salts. It can replace phosphorus-containing water treatment agents to avoid eutrophication and secondary pollution of water bodies.

Main Specifications

Appearance: Uniform liquid, no mechanical impurities

Active matter content: ≥20%

Density: 1.0-1.2g/cm3

pH value (1% aqueous solution) : 6.0-7.5

3.2. ERZG-2 corrosion and scale inhibitor

This product is a product developed by our company for oilfield sewage. It can form stable complexes or chelates with calcium, magnesium, strontium, barium and other ions in the water, and has good scale inhibition performance. It can form on metal surfaces. The protective film plays a role in corrosion inhibition, and both the corrosion inhibition and scale inhibition effects can meet the technical requirements of the oil field. It is stable under high temperature and high pH value and is not easy to be hydrolyzed.

Main Specifications

Appearance: red brown uniform liquid

pH value (1% aqueous solution): 5.0-9.0

Solid content:>25%

Solubility:Water soluble

4. Application case

Our company's products are widely used in domestic oil fields of PetroChina and Sinopec, especially in Shengli Oil Production Plant, Dongxin Oil Production Plant, and Tahe Oilfield No. 1 Oil Production Plant. They are also exported to Kazakhstan, Indonesia, Sudan and other countries. After that, it greatly alleviated the on-site fouling and corrosion, and achieved good results.

On October 13, 2008, after 186 days of operation in Well 143-Deviated 46 in Shengli Oilfield, due to sucker rod and tubing scaling, the well was seriously repaired.

Photo of running 186 downhole pipe string without slow-release scale inhibitor:

Using our company's slow-release scale inhibitor, add 40mg/L every day, after 400 days of operation, the oil well string was put forward for observation, and the effect was found to be good, and no corrosion and scaling phenomenon was found.

Photograph of downhole pipe string after 400 days of operation with slow-release scale inhibitor:

5. Service Process

The slow-release and scale-inhibiting technology mainly uses corrosion and scale inhibitors to solve the problem of corrosion and scaling in oil fields. However, there are many types of corrosion and scale inhibitors and are highly targeted. Indoor and on-site tests must be conducted according to the actual corrosion and scaling conditions. , Choose different corrosion and scale inhibitors to achieve the best results. This requires a professional chemical technology service company to conduct multiple rounds of tests to screen and determine the best corrosion and scale inhibitor program.

Yirui has a rich sample library of corrosion and scale inhibitors and will give chemical technology service companies more options to design more effective formulations.

If you are interested in our products or technology, you can follow the process below:

5.1 Please provide as much detail as possible the basic information of your current oilfield corrosion and scaling, as well as oilfield water quality reports, scale samples, etc.

5.2 Communication via email or social software, mainly to communicate and dock technical and business information.

5.3 ERUI provides samples and screening plans upon request.

5.4 Confirm the needs and direction of cooperation, and sign the cooperation intention agreement.

5.5 Provide overall solutions, process design, products or on-site construction guidance services according to the contract.

Crude Oil Demulsification Technology

Water Shutoff and Profile Control Technique

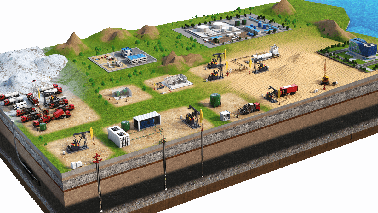

We demonstrate the working scene of oil and gas energy field, which help you quickly select the products you need.