ERUI:EFFICIENT SUPPLY CHAIN

ERUI:EFFICIENT SUPPLY CHAIN

Expandable Tubular Technology

Expandable Tubular Technology is a system for increasing the diameter of the casing or liner of an oil well by up to 30% after it has been run down-hole. (From Wikipedia )

Contents

In this article, we will talk about 5 parts about expandable tubular technology.

Part 1: 4 common problems in the drilling industry

Part 2: Introduction of Expandable Tubular Technology

Part 3: Advantages of Expandable Tubular Technology

Part 4: Applications of Expandable Tubular Technology

Part 5: Application of Expandable Screen Technology

Part 1. 4 Common Problems in the Drilling Industry

Industry Background

With the increase of deep well and ultra-deep well developing, drilling is becoming more and more difficult, and oil companies are more and more sensitive to input-output ratio. Here are 4 common problems we may face in the drilling and oil recovery process:

Problem 1: The deep well and complex well are easy to meet the complex formation of leakage, high pressure and so on.

Problem 2: The completion casing of the conventional sidetrack well is too small, the tail pipe is easy to leak, and the production is limited in the later stage.

Problem 3: The old well casing is seriously damaged, and the traditional technology cannot solve the technical problems of long well section and multi-well leakage.

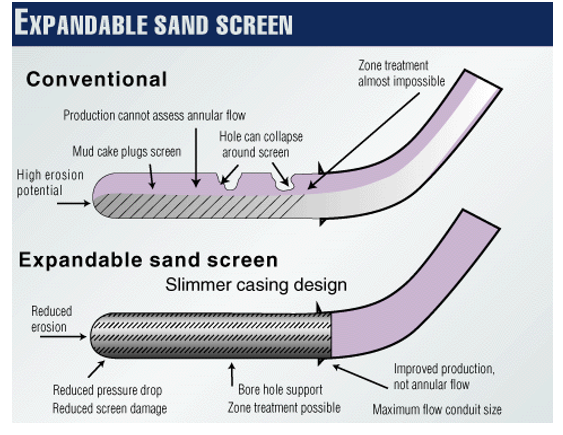

Problem 4: Because of the small internal diameter, the conventional screen is easy to cause sand blockage and other problems.

Expandable Tubular Technology can solve the above 4 common problems and has been becoming one of the core technologies of the oil drilling industry in the 21st century.

You may wonder why Expandable Tubular Technology is a perfect solution, here's why:

Part 2. Introduction of Expandable Tubular Technology

Why Expandable Tubular Technology is a perfect solution?

Expansion pipe is a kind of casing made of low carbon steel through special treatment, due to the low carbon content, the expansion pipe is more flexible than the normal casing.

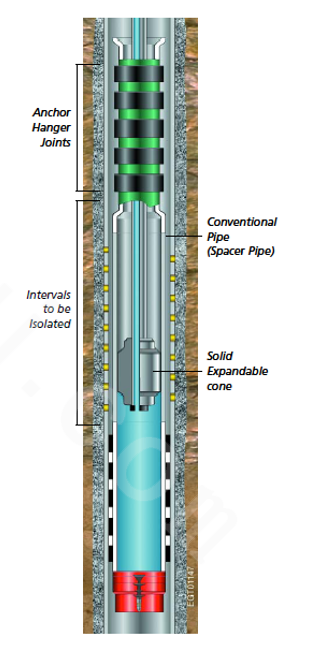

Expandable Tubular Technology is to remove the expandable pipe into the well, through the method of cold extrusion, the pressure or tension provided by mechanical or hydraulic pressure causes the expansion tool to expand the inner diameter or outer diameter to the size of the design by expanding the hole in the casing pipe. In simple terms, the expansion tubular technology is to transfer the cold expansion process from the factory workshop to the complicated working conditions of thousands of meters underground.

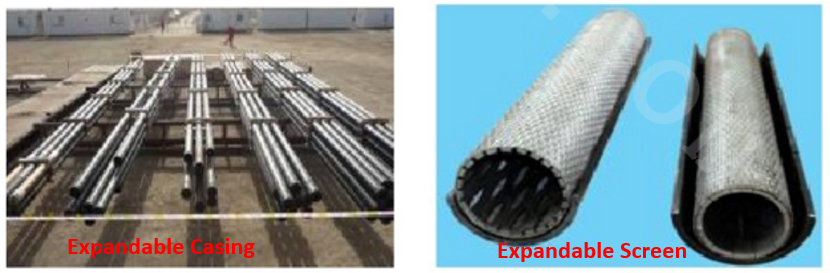

At present, the expansion pipe is divided into two types: Expansion Casing and Expansion Screen.

Part 3: The Advantages of Expandable Tubular Technology

1. It can effectively solve the well wall stability problem of complex formation.

2. Reduce the borehole taper, increase the depth of the casing, and enlarge the well completion size.

3. The size and casing number of the upper hole can be reduced.

4. Repair the damaged part of the casing.

5. The completion has greater flexibility.

6. It can improve the sealing effect of the tail pipe hanger.

7. The cost of drilling can be greatly reduced.

8. It can replace gravel pack technology and reduce well completion cost.

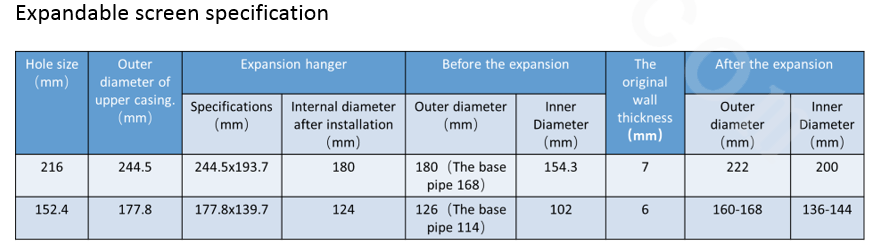

Here are some data about before and after the expandable tubular technology:

Part 4. Applications of Expandable Casing Technology

Application 1: Open hole liner system

The problems that can be solved are as follows:

Application 2: Casing liner system

The problems that can be solved are as follows:

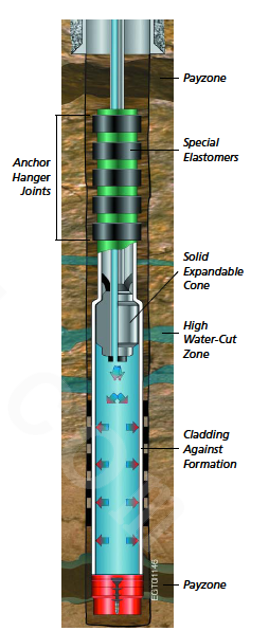

Application 3: Open hole clad system

The problems that can be solved are as follows:

Application 4: Flexible clad system

The problems that can be solved are as follows:

Part 5. Application of Expandable Screen Technology

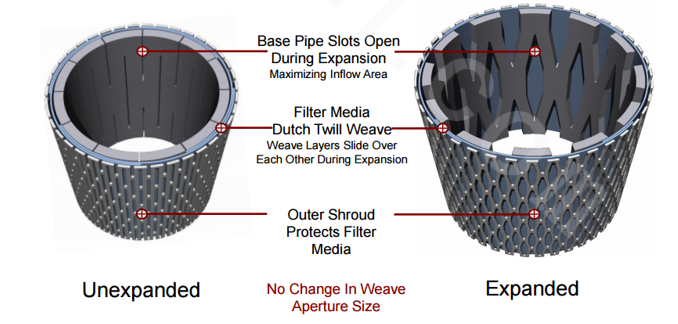

The expandable screen sand control technology provides a new method of large diameter hole sand control,and the application of expandable screen in casing well and open hole well is realized.

The problem of traditional screen pipe:

The advantages of the expansion screen:

You can click to >>contact us<< or directly by phone or email:

TEL.: 400-820-9199

E-mail: sales@erui.com

Efficient Removal of Deeply Plugged Oil Well

Wellbore Cleaning Technology, Solutions, Tools

10 Cost-Effective Ways to Improve Drilling Efficiency & Rate (ROP)

We demonstrate the working scene of oil and gas energy field, which help you quickly select the products you need.