This type of Thermal Suit which adopts Dupont FR Antistatic fabrics with intrinsical flame retardant and conducting static function is applicable to industries such as petrochemical and gas liquidation etc.

Background:

The occupational health

protection for outdoor staff in the cold region remains at the level of passive

warm retention and effective active heating solution is still not available. The

existing thermal suit comprised of carbon fiber, low voltage resisting wire can

not be applicable to operation in the cold environment because of the defects

of lower heating temperature and failure in controlling temperature.

Space

Grade exothermal materials (temperature memory intelligent semiconductor

materials) is used as heating element and low voltage portable module (7.4V/5V)

is used as power supply. Intelligent materials can be exothermal to (80—110℃) under low voltage and provide high active heating and create a 45—90℃ internal circulating warm environment

within the thermal suit and It can be continuously used for 4-6 hours per

charge to settle down the problem of not hot for existing thermal suit in the

market and also be essential for occupational health protection for outdoor

staff in the cold region and first choice for outdoor active heating.

Having

adopted unique military industrial protective design, thermal suit has adjusting

functions fitting for length and fat or thin and can be adaptable to different

close body figure’s use! Heating plates placed on belly and back make body nice

and warm.

Operation

Principle

Temperature memory

semiconductor material itself possessing with physical properties of

temperature measurement, temperature controlling and heating adopted by thermal

suit is one kind of self-control temperature heating element. The materials can

sense the environmental temperature change and also offer corresponding

treatment to temperature change and conduct analysis, judgement and response to

increase or decrease resistance, thus developed heating products are provided

with energy saving property via variable power and higher reliability via

contactless temperature control and high safety advantage;

Thermal

suits features are as follows:

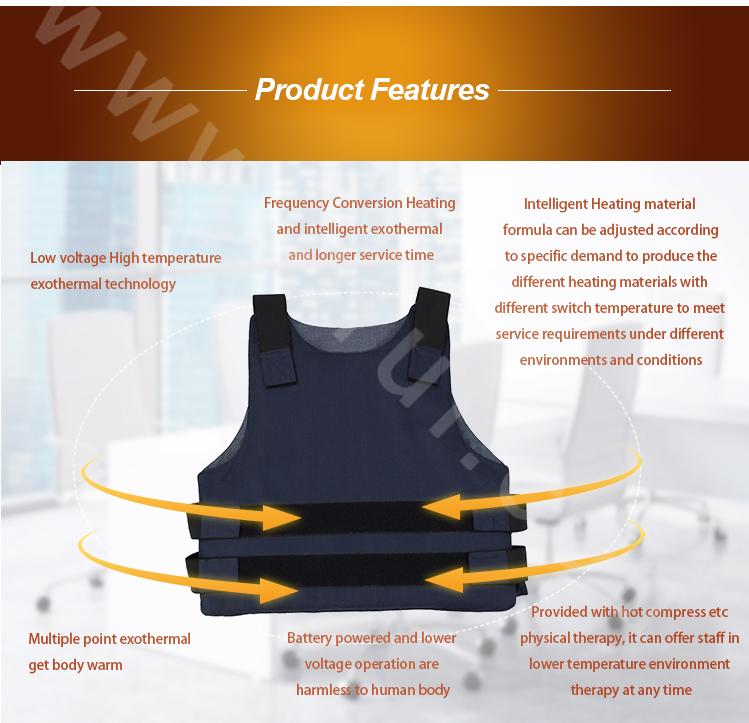

1) Low voltage

High temperature exothermal technology

2) Frequency

Conversion Heating and intelligent exothermal and longer service time;

3) Multiple

point exothermal get body warm;

4) Intelligent

Heating material formula can be adjusted according to specific demand to

produce the different heating materials with different switch temperature to

meet service requirements under different environments and conditions.

5) Provided

with hot compress etc physical therapy, it can offer staff in lower temperature

environment therapy at any time;

6) Battery

powered and lower voltage operation are harmless to human body.

Differentiation

Advantage

1. High Magnification Thermal Technology

High temperature can be obtained through

portable power supply and 45—90℃ internal warm environment is created

with surging heat. 105-115℃ can be reached under low

voltage 5-7.4V exceeding two times of other products;

2. Self-Constant Temperature Technology

Possessing with self-constant controlling

temperature capacity, new material with innovative technology, can self-control

temperature to keep constant temperature through increasing or decreasing the

resistance, more intelligent than other materials;

3. Leading energy saving technology

New materials will adjust power according to

the itself-energy absorbed speed, materials will be breathing type heated and

it’s power will depend on heat loss,

rate, If having entered into warm environment, materials will decrease

the power automatically and more energy saving comparing to other materials;

4. Super safe Temperature switch technology

With the highest temperature protection character,

material eradicates fire etc potential safety risks, Being provided with

ceiling temperature, if materials temperature reach the preset temperature

memory point and resistance will increase infinite to cut off the circuit and

more safer fundamentally comparing to other materials.

Thermal

Suit Structural Design

1. Super Heating System: As the core layer, temperature memory intelligent heating

material is overlaid with super aluminum radiating layer can make the heat

energy output gushingly;

2. Special Thermal Insulation System: HEAT thermal reflection layer+ Super silk

cotton insulation layer+ Leakage proof layer+ Special cotton insulation layer,

four level insulation layer will keep the heat longer and give full play to

variable power of intelligent material;

3. Dual Thermoregulation System: Hi-energy Lithium Battery Output power shift gear

+ material self-regulating power function, dual thermoregulation system built

the automatic constant temperature system within thermal suit;

Military

Industrial special self-adaption physical

design: Unique military industrial protective equipment design let the

thermal suit fit different figure with different height, fat and thin.

Scientifical ergonomic design let the warm surround the whole body, Thermal suit

close to body completely and can conduct the heat into body steadily and bring

you warmth next to the skin.

Use

Features

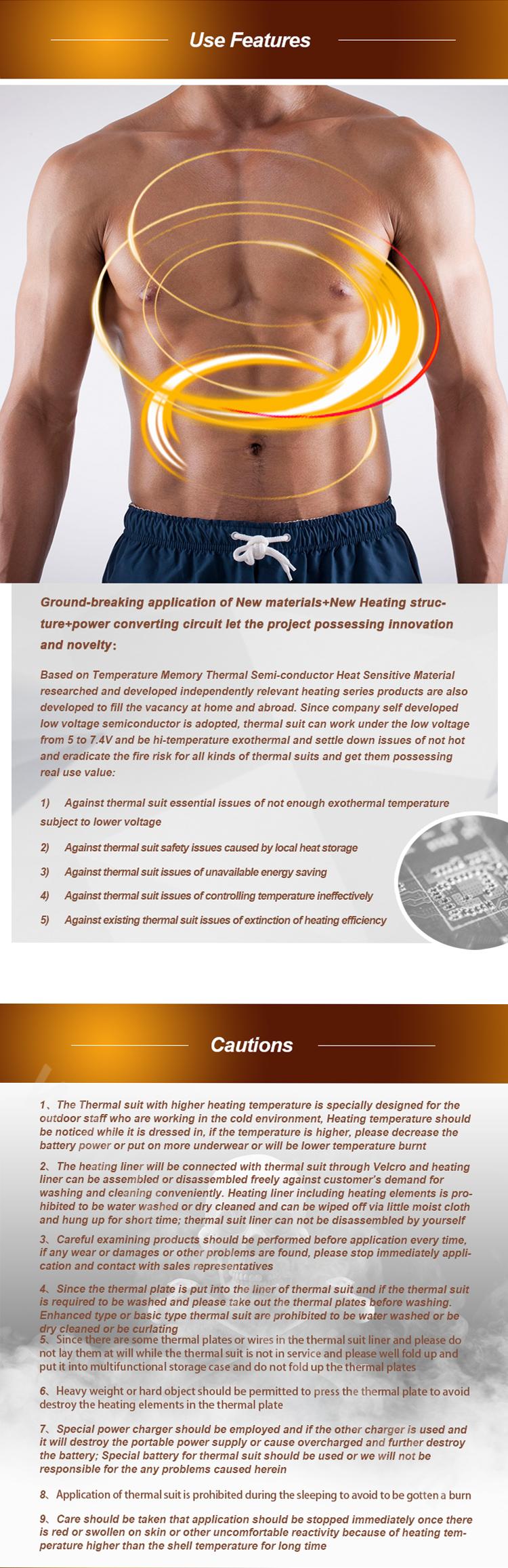

Ground-breaking

application of New materials+New Heating

structure+power converting circuit let the project possessing innovation

and novelty:

Based on Temperature Memory Thermal Semi-conductor

Heat Sensitive Material researched and developed independently relevant

heating series products are also developed to fill the vacancy at home and abroad. Since company self

developed low voltage semiconductor is adopted, thermal suit can work under the

low voltage from 5 to 7.4V and be hi-temperature exothermal and settle down

issues of not hot and eradicate the fire risk for all kinds of thermal suits and

get them possessing real use value:

1) Against thermal suit essential

issues of not enough exothermal temperature subject to lower voltage;

2) Against thermal suit safety issues

caused by local heat storage;

3) Against thermal suit issues of unavailable

energy saving;

4) Against thermal suit issues of

controlling temperature ineffectively;

5) Against existing thermal suit issues

of extinction of heating efficiency;

Cautions

1. The Thermal suit with higher heating

temperature is specially designed for the outdoor staff who are working in the

cold environment, Heating temperature should be noticed while it is dressed in,

if the temperature is higher, please decrease the battery power or put on more

underwear or will be lower temperature burnt;

2. The heating liner will be connected

with thermal suit through Velcro and heating liner can be assembled or

disassembled freely against customer’s demand for washing and cleaning

conveniently. Heating liner including heating elements is prohibited to be

water washed or dry cleaned and can be wiped off via little moist cloth and

hung up for short time; thermal suit liner can not be disassembled by yourself.

3. Careful examining products should be

performed before application every time, if any wear or damages or other

problems are found, please stop immediately application and contact with sales

representatives.

4. Since the thermal plate is put into the

liner of thermal suit and if the thermal suit is required to be washed and

please take out the thermal plates before washing. Enhanced type or basic type

thermal suit are prohibited to be water washed or be dry cleaned or be

curlating.

5. Since there are some thermal plates or

wires in the thermal suit liner and please do not lay them at will while the

thermal suit is not in service and please well fold up and put it into

multifunctional storage case and do not fold up the thermal plates;

6. Heavy weight or hard object should be

permitted to press the thermal plate to avoid destroy the heating elements in

the thermal plate;

7. Special power charger should be

employed and if the other charger is used and it will destroy the portable

power supply or cause overcharged and further destroy the battery; Special

battery for thermal suit should be used or we will not be responsible for the

any problems caused herein.

8. Application of thermal suit is

prohibited during the sleeping to avoid to be gotten a burn.

9. Care should be taken that application should be stopped immediately

once there is red or swollen on skin or other uncomfortable reactivity because

of heating temperature higher than the shell temperature for long time.

Arc Protective

Explosive Proof Intelligent Thermal Suit (Vest Type): This type of Thermal Suit

which adopts arc protective fabrics and completed with explosive proof battery

is applicable to application in hot-line work within operation situation with

combustible gas and outdoor electrical operation;

Explosive Proof Type Thermal Suit

Three explosive proof measures for thermal suit ensure

the safety

Having adopted three

explosive proof type, explosive proof type thermal suit ensure it’s application

in the hazardous locations.

1) Intrinsic safety type Circuit

design:

The

electronic regulation and control circuit is designed to intrinsic safety

circuit, namely, circuit itself is intrinsic safety and applicable to all

hazardous locations.

2) Set up

explosion isolation measure:

A

explosion isolation case is added to the Battery to ensure battery running

safely.

3) Encapsulation

process to be performed:

The

components produced potentially arc, spark or high temperature to ignite the

explosive mixture within the thermal suit should be encapsulated to prevent

these electrical components contacting with explosive mixture.

Technical Parameters:

Fabrics: 200g Dupont Nomex IIIA, 120g Dupont 50/50 FR Lining, filling is 3m 100g Thinsulate, YKK Nylon Zipper, FR velcro;

Four pieces of thermal energy plate,7.4V/6000mAh polymer lithium battery with explosive proof enclosure