ERUI:EFFICIENT SUPPLY CHAIN

ERUI:EFFICIENT SUPPLY CHAIN

Introduction of Drilling Efficiency & Rate (ROP)

Rate of Penetration (ROP) is one of the important factors influencing the drilling efficiency. Since cost recovery is an important bottom line in the drilling industry, optimizing ROP is essential to minimize the drilling operational cost and capital cost. How to improve ROP efficiently? Is there any cost-effective way?

In this article, we will talk about 10 commonly used ways in the drilling industry to help you improve your drilling efficiency & rate (ROP) successfully.

10 Cost-Effective Ways to Help you Improve Drilling Efficiency & Rate (ROP)

4. High efficient milling tools

6. Mini-step reaming while drilling tools

8. Bit Anti Stick-slip Tools (AST)

9. Torsion and impact compound rapid drilling tools

10. Controllable variable diameter stabilizer

There is a developed coring technology and matching coring bits for conventional coring, form keeping coring, directional and horizontal wells coring, coring in air drilling, hydrates pressure and temperature preservation coring, cores post treatment etc. At the moment, there are two series and 11 types of coring tools to meet the needs of conventional coring, form keeping coring and sealed coring for the soft, broken, deep wells and shale formations with various wellbore sizes, and the core recovery percentage is more than 90%.

There is capability in designing and developing various tools for drilling casing exits, and SZ series of conventional, recyclable, recoverable, integrated whipstocks for 5-1/2〞~24〞casings and XZ series of combined mill taps, as well as ZX series of watermelon mills. Meanwhile, there are TDX series of casing section mills for 5-1/2〞~9-5/8〞casings.

Success Story:

They are used in hundreds of sidetrack wells in Shengli, CNOOC, Xinjiang, Qinghai, Zhongyuan, Jiangsu, Huabei, Daqing, Sichuan, Yumen oil fields and overseas oil fields in Burma, Kazakhstan etc. with the window sidetracking success rate of 100%.

A. The window milling section maximum depth of Ha-9C2 well:6471.6 - 6476.80m

B. The window milling section maximum angle of Zhuang 202 well and Ping-10 well: 90.5°

C. The maximum casing sidetracking (window) size of WZ12-1W-A7H well: 24″drilling riser

D. Dual casing sidetracking with 13-3/8″and 24″drilling risers for SZ36-1E24h1 well

E. The maximum 7″ casing milling section deviation of Yi 173-5HF7 well is 30.67°

F. The maximum 7″casing milling section depth of TK837CX well is 5527-5557

3. Casing Wear Protection Sub

For the purpose of solving the casing wear and drilling torque problems in extended reach wells, deep wells, ultra-deep wells or highly deviated wells, various types of casing wear protective (torque reduction)connectors used for 7″~13-3/8″casings are developed. A whole set of tools is processed and manufactured with high-strength alloy structural steels and drilling fluid lubrication, and has the advantages of simple structure, long service life, low risk, easy installation and disassembly.

Success Story:

They are used in Shengli, CNOOC, Xinjiang, Zhongyuan, Huabei, Jidong, Jilin, Sichuan oil fields in China and overseas oil fields in Burma, Kazakhstan and other countries. The casing wear prevention effects are highly recognized by the owner companies.

4. High Efficient Milling Tools

There is capability in researching and developing customized, serialized highly efficient grinding&milling tools and technical services. Highly efficient mill shoes, pilot mill shoes, washover shoes and downhole tools have advantages of high milling speed, long drilling footage, smooth grinding and milling etc.

Success Story:

At the moment, they are used in Shengli, CNOOC, Xinjiang, Zhongyuan, Huabei, Jidong, Jilin, Sichuan oilfields in China, having achieved significant application effects.

A series of PDC underreamers is developed, using PDC composite chips as the cutting edge, which can achieve the purpose of reaming while drilling with the help of pressure drop generated by the piston nozzle to drive the reamer wings. The product has the advantages of mature and advanced technology, high speed of reaming, high efficiency etc.

Success Story:

In oil fields of Tarim, Zhongyuan ,Shengli , Jiangsu, Qinghai, Ningxia and overseas, such as Myanmar, Turkey and other countries, the products have been widely used, among which, the YK216-280 type reaming tools were used for Chu-1 well at the depth of 7226m-7513m to carry out reaming operations by 5 sections for the salts and gypsum rocks with an average penetration rate of 8m / h, and a record of the deepest construction in 8-1 / 2 " wellbore reaming has been created.

6. Mini-Step Reaming While Drilling Tools

Mini-step reaming while drilling tools with a total of 6 sizes, which are suitable for 118~311.2mm wellbores, have been developed to solve the problems of round trip, electrical logging, running casing difficulties etc. generated by necking, thick cutting bed, micro overall angle change rate, mini-step and so on in drilling process. The reaming tool can create a wellbore slightly larger than the conventional bit size while drilling, meanwhile, it has the function of back reaming.

Success Story:

The products have been applied to 660 well times in Shengli, Nanyang, Karamay, Dianqiangui, Jidong oil fields and CNOOC, etc. with remarkable application effects.

7. Hydraulic Agitator

The hydraulic Agitator is developed by using the axial vibration load of the drill string produced by the hydraulic pulse, which has overcome the friction between the drilling tools and the wellbore, improved the transmission efficiency of downhole weight on bit (WOB), increased the control precision of the tool surface and extended service life of bits.

Success Story:

The products are applicable to deviation wells, extended reach wells, shale gas reservoirs drilling, and are particularly effective for sliding drilling with a steerable motor, at the moment they have been successfully applied to 20 well times.

Technical parameters

A. Temperature resistance 175℃

B. Pressure resistance 100MPa

C. Length 6.8m

D. Weight 680kg

E. Diameter 96-203mm

F. Working displacement 10-50L / s

G. Working frequency 15Hz

H. Tools pressure loss 3-4MPa

8. Bit Anti Stick-slip Tools (AST)

The bit Anti Stick-slip Tools (AST) can automatically adjust the drilling torque, protect the drilling tools and optimize the rock breaking efficiency. They can significantly improve the work stability of the PDC bits, prevent bit from damage, extend the service life of bits, meanwhile, increase the bits’ rock breaking energy and improve bits' rock breaking efficiency.

Success Story:

The products are applicable to straight well drilling, drilling with a steerable motor, rotary steering drilling and so on.

Technical parameters

A. Temperature resistance 175℃

B. Pressure resistance 100MPa

C. Length 3.8m

D. Weight 380kg

E. Diameter 96-203mm

F. Start torque adjustable

G. Maximum weight on bit (refer to bit)

H. Maximum drilling rate (refer to bit)

9. Torsion and impact compound rapid drilling tools

Torsion and impact compound rapid drilling tools can convert the fluid energy into mechanical energy, provide high-frequency torsional impact to the bit, establish the rock breaking energy compensation mechanism of the near-drill bit to reduce the "sticking and slipping" problem, and make the PDC discontinuous and unstable drilling process become as continuous and stable as possible, thereby to increase the penetration rate, protect the drill bits and other drilling tools and increase the drilling efficiency.

Success Story:

The products have been successfully applied to more than 168 well times in oil fields of the East China Sea, the South China Sea, Xinjiang, Qinghai, Shengli oil and shale gas, coal bed methane and other oil and gas reservoirs with the footage of over 40, 000 meters, and the average penetration rate has been increased by 59%, what's more, the records have been broken for 7 times in working blocks.

10. Controllable variable diameter stabilizer

An 8.5 "variable diameter stabilizer is developed to achieve downhole controllable variable diameter operations by starting and stopping the drilling pump as a control method, therefore it can continuously control the wellbore trajectory, improve the wellbore quality, shorten the drilling cycle and reduce the drilling costs.

The application of the products in Ying87- deviation well-50 and Xin100-deviattion well-1 shows that the tool is easy to operate, has reliable performances, long service life and excellent stability, thereby, it can increase penetration rate by more than 50% in the inclined section.

You can click to >>contact us<< or directly by phone or email:

TEL.: 400-820-9199

E-mail: sales@erui.com

Efficient Removal of Deeply Plugged Oil Well

Wellbore Cleaning Technology, Solutions, Tools

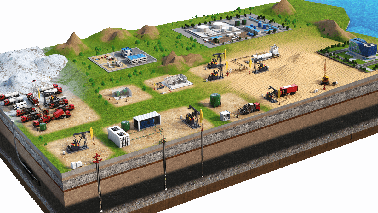

We demonstrate the working scene of oil and gas energy field, which help you quickly select the products you need.